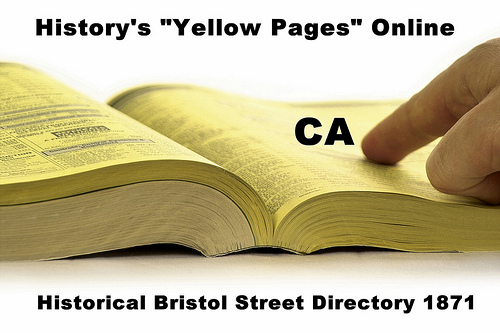

A couple of nice machined car cup holder china images I located:

CA – Historical Bristol Street Directory 1871

Image by brizzle born and bred

Mathews’ Bristol Street Directory 1871

Caledonia Location, Sion Hiil to Mall Buildings, Clifton

Mrs Thomas Butterworth

Cooper Reade, surgeon

Mary Powell, lodging home

Jesse Peachey, lodging property

Mrs. Watley

Mrs Luxmore

Misses Davey

Robert H. Rickards

William Cross, surgeon

Julius Miles

John M. Walcot

Mrs S. Howe

Mrs J . M. Cholmeley

Mrs Sarah Woodley

Mrs Whish –

Miss Farleigh, lodging home

William Adams, lodging home

C. J . Rumbold

Henry Thomas Bridges

Samuel Cryer, lodging house

Mrs Povey, lodging house

Mrs General Roberts

George Young, lodging house

Miss Might

Miss Taverner

Mrs H. Forsyth

Rev. Ralph Lambton Hopper, MA.

Miss Payton Sadler

John Southwood

Jean Van Houtrive

Mrs Elizabeth Brown

Dr. Henry Marshall

Mrs Henry Seymour

Miss Burrow, lodging residence

Col. Saville

Callowhill Street, Leek Lane, Milk Street to Clark Street

William Penn the founder of Pennsylvania married Hannah Callowhill.

Leek Lane connecting Broadmead and Milk Street (which ran from Horsefair to Newfoundland Street).

The site is now covered by the part of the Broadmead shopping centre that is adjacent to Cabot Circus.

C. Hart, baker

William Higgins, boot maker

Thomas Hill, vict, the Apollo (pub)

Elizabeth Jones, vict, Prince of Wales (pub)

Prince of Wales, Callowhill Street

1868 Mary Ann Roberts / 1869 John Jones / 1871 – 72 Elizabeth Jones / 1874 James Willey / 1875 Thomas Morgan / 1876 Henry Tucker 1877 – 79 William Hacker / 1882 – 83 Henry Hathway / 1885 – 89 Thomas Hill / 1891 Eliza Ann Hill / 1892 John Thomas 1896 William Burgess / 1897 – 99 Thomas Hill / 1901 Arthur Dare / 1904 W. J. Rodway / 1906 John Fitter / 1909 – 14 William Blackmor James Harding.

Cambridge Park, Redland, Durdham Down

Mrs Shuttleworth

Mrs Hussey Gould, Dorset lodge

Rev. ?. Barnes

Rev. Edward. St. Jn. Parry, Tudor residence

Cambridge Place, Harley Place to Canynges Road, Clifton

Mrs O. C. Lane, Seymour villa

Miss Edwards

William Thomas Palmer

Mrs Ellis

Edmund Edmunds

Mrs Annie Bowling

Mrs Thomas Trimnell

William Richards

Mrs Mary Hume

Mrs Jane Robinson

Richard Sanders

Mrs Elizabeth Gullick

Emile Arnold Praeger, artist and engineer

Miss Le Grice, piano and singing

?. Wilkins

Mrs Carus Wilson

Mrs Margaret Keir

William Snook, lodging house

Miss A. Townsend

Miss L. Palmer

Cambridge Spot, Seymour Road, Stapleton Road

See Seymour Road

Cambridge Street, Wells Road to William Street, Totterdown

William Ashton Primrose, Cambridge lodge

Thomas Powell, Raglan residence

Joseph Coles, fly proprietor

Henry Young

Theodore Young

Stephen Masters

John Howell

Thomas Vicary

William Angle

John Westcott, Devonshire dairy

Phillip Levering, tea dealer

Phillip Light, carpenter

Robert Macfarlane

Richard Richards, miller

Cambridge Terrace, Cambridge Street to Richmond Street, Totterdown

George William Brackstone

John Tovey, painter

Richard Richards, draper

Thomas Pearson

Frederick Kneller

Thomas Hurford

Jos. Lowden

Mrs. Hall, ladies boarding school

John Mortimer, clerk

Henry Woodman

John Adamson

John Jarrett

James Rathbone

Charles Sibley

John Tucker, grocer & beer retailer

Cambridge Terrace, Seymour Road, Baptist Mills

See Seymour Road

Camden Cottages, Stapleton Road

See Stapleton Road

Camden Terrace, Clifton Vale to Hotwell Road

Robert Purnell, lodging home

Mrs Hannah Hitchcock

Mrs Elizabeth Carter

Robert Marks

George M. Carlisle

John Davey

Mrs Hazard

George Drummond, Channel Docks Co.

Alfred Emblin

Frank Mulleny

Capt. William Outerbridge

John Put on, accountant

Henry Jones

Peter Bull

Henry George Raymond, carpenter and contractor

Robert Williams

Mrs Mary Williams, dressmaker and milliner

John Gardiner Fraser

Camden Terrace, Guinea Street, Redcliff

www.flickr.com/pictures/brizzlebornandbred/2060447406/

See Guinea Street

Camden Terrace, Cotham Road, South

Campbell Street, Grosvenor Road, St. Paul’s

Mrs Ann Robertson

John Waters

James Harry. Lovell, professor of music

Mrs Brief

Mrs Ann Lewis

Joseph Evans Pearce

Henry Fuller Stokes, sign-writer on glass and wood

William Henry Poole

Henry Fullford

James Taylor

Tom Pusey

Thomas Dunn

Henry Wyatt

Thomas Tarr

William James Brown, com-trav

Thomas Mitchell, carpenter

Thomas Naylor

Josiah John Brain Taylor

William Gibbs

James Underhill

Joseph Norman

John Clyne

Campbell Terrace, Baptist Mills

Canning Street, Pennywell Road

Canon Spot, Folly Lane, Dings

Canon Street, near London Inn, East street, to North street, Bedminster

In Cannon Street, Moses Reynolds complained of Henry Williams burning pigs and melting fat at his piggery, but nothing at all seems to have been accomplished about this complaint.

In addition to the nuisance caused by deposits of filth and the close proximity of animals to houses, not least was the effect upon the environment by regional sector.

In 1853 the Bristol Board of Overall health asked Messrs Stephen Cox and Co to discontinue the practice of burning Wet Tan at their premises in Whitehouse Street. Cornish and Parnell, solicitors for the company, maintained that the burning of Wet Tan was not a nuisance, neither did it give off any noxious or offensive odour.

Fleshings and butcher’s offal were widespread offenders, with each other with slaughterhouses. It was decided to advertise in the local press requesting all butchers and slaughterhouse keepers to register with the Board. By 1894, the following slaughterhouses had been registered in Bedminster.

Charles Norris, painter

Susan Hobbs, shopkeeper

William Worgan, marine retailer dealer

Wm. Franklin, com-trav Eldon cottage

William Rowe, vict, London Tavern (pub)

London Inn, Cannon Street

1775. William Morgan / 1816 – 20. Thomas Lamprey / 1822. Charles Lamprey / 1823 – 30. Charlotte Lamprey 1831 – 34. Mary Clements / 1837. Charlotte Lamprey / 1839 – 42. John Abbott / 1843. Henry Williams / 1844 – 50. John Spiller 1852 – 53. John Thompson / 1854 to 1857. Joseph Bridgeman / 1858. John Wall / 1860. Jeremiah Reay / 1863 – 67. Thomas Farmer 1868 – 89. John Rowe / 1891 -1904. Aubrey Lock / 1906. Frederick Carr / 1909. Emma Carr / 1914 – 17. Harry Hopkins 1921 – 25. Charles Marr / 1928 – 31. Edward Godwin / 1935 – 38. William York / 1944 – 53. Albert Tew / 1960. E. A. Bird 1975. F. A. Hennessy.

Canon Street, St. James’s churchyard to Decrease Montague St

Mrs Gay

Mrs Murdon

John Gordon, greengrocer

Benjamin Canning, cabinet maker

David Keely

Thomas Beedell

Presbyterian Night School

George Cavil, grocer

Charles Slade, vict, Canon Tavern (pub)

Cannon Tavern, Canon Street

1775 James Nowell / 1837 – 39 J. Bidgood / 1840 J. Hurbert / 1844 Maria Collier / 1847 – 48 William Jones / 1849 George Baggott 1851 Joseph Jarvis / 1853 – 56 James Fouracres / 1857 to 1859 Robert Green / 1860 – 65 Richard York / 1867 – 69 John Lewis 1871 Charles Slade / 1872 to 1877 Christopher Broom / 1878 – 79 James Kemp / 1882 – 83 Charles Lapham / 1885 Chris. A. Broome 1886 K. Scriven / 1888 George Cornish / 1891 – 93 James Hole / 1896 John Crocker / 1897 – 99 Henry Wyatt.

James Webber

Henry Street

Thomas Knill

Charles Ley

William Evans

Presbyterian School

James Porch

Evan Francis, boot maker

Richard Mountain

Thomas Bucknall

George Gillard

Mrs Walsh

?. Hall

Canons’ Marsh, Gas works to Butts

The Bristol Gas Works

William Brent

George Rogers Thomas

Jones & Nash, timber merchants

F. K. Barnes and Sons, timber merchants

James Temple and Sons, slate and marble merchants

Liverpool Steam Packet Co. – G.W.H. Evans, agent

William Baker and Co. builders

Thomas Tyley, marble functions

James and William Peters, ship builders, Canons’ Marsh Graving Dock

Heber Denty, timber merchant

George H. Rains & Co. wire, hemp, rope and sail, companies

Charles Roach

John Wickham

John William King

Thomas Bowyer, vict, King George (pub)

King George Tavern, Canons’ marsh

1800 Elizabeth Bevan / 1816. John Bevan / 1820. John England / 1822 – 23 George King / 1826 – 31 John Bryant 1832 – 34 Ann Thorne / 1837 – 53 William Luens / 1854 – 67 William Winter / 1868 – 72 Charles Lea / 1874 – 78 Thomas Bowyer 1879 – 89 Ellen Godfrey / 1891 – 97 Richard Hancock / 1899 Eliza Hancock / 1901 Elizabeth Nichols John England also traded as a tiler and plasterer, in Rosemary Street.

William Howell

Ford and Canning, coopers and warehousemen

George Church

Michael Clark, grocer

William Lee, builder & slate merchant

Canynge‘s Road, Harley Location, Clifton Down to Durdham Down

Charles Arthur Jacobs, livery stables

Misses Fitton, Wellington villa

James Siston

William Baker

William Powell, Norland home

Mrs E. Graham

Robert Coles

(Somerset Spot – Somerset cottage)

Miss Harriet Spiring

Edward Bevan

William Beatson, M.D.

Mrs Buckingham, lodging house

Mrs Jane Waygood, lodging property

Miss Lane

Mrs A. Jameson

Charles Arthur Jacobs, riding master and livery stable keeper

John Pearce, dairyman

Mrs Hutton, Prospect home

The Misses Hendley, Somerset property

Thomas Proctor, Elmdale home

James Christopher Wilson, Farfield

Rev. Richard William Randall

Capt. Harry John Curteis, Clarendon villa

William Frederick Phillips, Coniston lodge

Alfred Newton Herapath, Penleigh villa

Charles Somerton, Norman villa

Dr. William Trotman, Energlyn

(Harley Place Reduced)

Miss Catherine Burges, Enfield villa

Mrs Louisa Pryor, Litfield villa

Capt. William Philips, Salisbury lodge

Mrs John Rickards, Trafalgar villa

Samuel Worsley, Arno’s villa

William F. Trimnell, Walton lodge

Edward Taleur Salt, Cambria villa

Mrs Fanny Waters, Preston villa

Miss Fenton, St. John’s villa

Mrs Evered, Brighton lodge

Canynge Street, Portwall Lane

Named after William Canynges, whose mansion once stood in nearby Redcliffe Street.

Christopher Roberts & Co. drysalters and oil merchants

Henry Purnell, vict, Globe & Foresters (pub) bristolslostpubs.eu/page159.html

The Globe & Foresters was on the corner of Portwall Lane and Canynge Street. The buildings on this corner were demolished about 1980 and replaced with a vehicle showroom.

Cann’s Court, Trenchard Street, St. Augustines

Canning Street, Pennywell Road

Canning Street was off Pennywell Road if you had been travelling North, then it was on the left just previous the correct fork with Goodhind Street.

Captain Carey’s Lane, Old Marketplace Street to Ropewalk

Captain Carey’s Lane ran from Old Industry to Redcross Street/Ellbroad Street and was lost when the alterations had been made to construct the underpass and Old Market place roundabout (Temple Way underpass). So it would have been not too far from Penn Street.

John Herbert Crates, plumber

John Thomas

John Shea, marine shops

Richard Crocker, mason

Joseph Nicholls

Thomas Robins, last maker

Russell J . Thompson, boot maker

William Cardwell

Stephen Allen, locksmith

William Tull, marine stores

Harry Bessell, mattress manufacturer

Thomas Brookes, soda water manufacturer

Carlisle Court, Thomas Street

Carlton Place, North St. Bedminster. close to Hen & Chickens

Carlton Location, Victoria Street, Clifton

Carlton Spot, Queen’s Road, Richmond Park, to Park Place

William Hammond, Carlton villa

Mrs Mary Elizabeth Thackery, Carlton lodge

Mrs Mary Ann Spencer, lodging home

Joseph Spencer, florist

Mrs Elizabeth Tolkein

William Leaver, lodging property

Christopher Baugh

Rev. James Charles Stafford

The Misses Cripps

Counsell & Fewings, lodging house

Mrs Shepherd

Miss Haynes

Mrs and Miss Simpson

Miss Bush

William Wilberforce Jose, Weston villa

Myles A. Clark, Carlton residence

William Francis de Viemes Kane, Buxton villa

George Brittan, Albion villa

Carlton Location, Pennywell Road

Carmarthen or Grays Court, Temple Street

Carolina Avenue, Carolina Row

Carolina Row, King Square to Gay Street

Lewis James Hill

?, Strange

William Burt, tailor, and so on

H. Woolford

Charlotte Hart

George Denny

Mrs Eliza Partridge

John Bowden

Thomas Durant and Son

(Carolina Avenue)

Francis William Loft

Eliza Chandler

Edwin Tucker

Charles Crocker

Samuel Lewis, agent for European Insurance Company

Caroline Row, Highland Location, Durdham Down Blackboy

George Parsons

Henry Hughes, mason

Mrs tephens

Samuel Yeeles

Francis Pillinger

Jabez Bownce

Joshua Edwards

Mrs Tudball

Caroline Location, Hotwell Road, opposite Brunswick Location

Edwin Godfrey

Mrs Wilds

Thomas Evans

James Whitlow

James Stooke

George Davis, carpenter

Mrs MacCullook, lodging house

M. Nathan, lodging property

Joseph Randall, vict, Packet Home (pub)

Packet Residence Tavern, Caroline Spot

1839 – 42. William Capper / 1848 – 49. Samuel Cross / 1851. William Court / 1853 – 69. William Davies / 1871 – 87. Joseph Randall 1893. Agnes Randall / 1899. Priscilla Hamilton / 1901 – 09. Richard Thorn / 1914. Mrs. E. Ashford / 1921. Edward Jones.

William Seville

William Wookey, coal merchant

Edward Hunt

James Cavill

Caroline Location (Little), Hotwell Road

Carpenters Court, Horsefair

Carpenters Court, Haberfield Street, St. Philips

Cart Lane, Temple Street

Carters Buildings, Portland Street, Clifton

Castle Court, Quarry, Durdham Down

Castle Green, Narrow Wine Street to Castle Street

Harry Pethybridge, vict, Odd Fellows’ Hall (pub)

Odd Fellows’ Hall, Castle Green

1863 James Walker / 1866 Alfred Dyke / 1867 Alfred Osborne / 1868 to 1876 Henry Pethybridge / 1877 E. McGill 1879 – 86 Thomas Beavis / 1887 to 1888 Walter Burridge / 1889 Ellen Elizabeth Atkinson / 1891 Harrison Leggett 1892 – 1901 George Harris / 1904 – 06 George Derbey / 1909 Walter Hale on the 25th March 1888 the Odd Fellows’ Hall was taken on a 14 year lease at a rent of £24 per annum by James Lockley, brewer of Lewin’s Mead. The lease was one particular of 22 sold by James Lockley to the Bristol United Breweries Restricted on the 25th March 1892 for the total sum of £11,000.

G. Smith, Sutton & Co. parcel o?ice

Mrs Gitson, dress maker

Carver, Jefferis & Co. hat companies

James Smith & Sons, boot & shoe makers

Hellier, Wills, & Hurndall, oil, color and varnish merchants

Bristol Dispensary, W. Pollard

Thomas Glass & Co., hat and cap producers

Chapel

Castle Green Day School, Masters, Thomas David Hirons and James Smalley

Methodist New Connection Chapel

James Habgood, iron & metal merchant

Stabbins & Tyler, hat & cap producers

Harding & Vowles, builders

John Charley

Ann Jenkins, lodging house

Robert Williams

Henry Gregory, functioning silver-smith and engine turner

Mary Spring, cooper

George Popham, ironmongers

?, Pearson, hat manufacturer

James Triggs, brush maker

Edward Kent, printer

Stephen West, glazier

George Hewlett

Joseph Brunt, vict, Friendship (pub)

Friendship, Castle Green

1853 – 60 Thomas Collings / 1863 – 67 Elizabeth Collings / 1868 – 71 Joseph Brunt / 1871 Elizabeth Collings / 1872 – 89 Matilda Brunt 1891 Edward Coome / 1892 – 96 Thomas Beavis / 1899 Sarah Beavis.

Mrs Culverwell, school

James Mizen

Mary Davis

Castle Green Sunday College

Glass and Betty, hatters

James Jones, printer

Castle Green Congregational Chapel

George Thomas Harris, working jeweller

Smith & Marsh, hat companies

Charles Hoskens, boot maker

Llewellins & James, coppersmiths, engineers, etc

George Henry Webber, vict, Cat & Wheel (pub) bristolslostpubs.eu/page22.html

On the corner with Tiny Peter Street, standing in 1606 the Cat & Wheel was re-built in 1900, some bits & pieces had been salvaged and are now housed in the Bristol City Museum. The later creating was demolished in 1969 for a new museum complicated which was never ever constructed. If standing these days it would be in Castle Park just opposite the entrance to the Galleries vehicle park in Newgate. The name above the door in this picture is W.T. Beavis which dates it to about the time of the inn’s demolition.

Castle Green Terrace, Castle Green

Castle Mill Street, Merchant Street to Narrow Wine St

Emanuel Long

Edward Lockstone, chemist

Thomas Beavis, beer retailer

Thomas Barriball, leather merchant

William Somers, engraver, etc.

John Powell, butcher

J . Smith, confectioner and baker

Amelia Bayntun, refreshment house

William James, carpenter

Jane White, shopkeeper

Henry Dyer, cabinet maker

Henry G. Parnall & Sons, scale beam & weighing machine manufacturers

James & Son, boot and shoe makers

Walter Fisher, ticket-writer & printer

W. Starr, wardrobe dealer

Henry G. Bishop, vict, Castle and Mill (pub)

Robert Price tag, timber merchant

Castle Street, Peter Street to Old Industry

John Williams, china warehouse

Henry Mundy, general ironmonger

Robert Pine, baker

John Thatcher, cabinet maker

S. C. Rossiter, linen draper

W. H. Vowles, brush & basket producers

Daniel Underwood, grocer

Rd. Batten Edgeworth, ironmonger

James Rogers, boot maker

George Bragg, ironmonger

Payne & Thompson, wholesale haberdashers

Llewellins & James, brass founders

William Hadden, butcher

George Popham, dining rooms

Robert Hill, cutler

John Edwin Saunders, milliner, etc

R. King, child linen warehouse

Edwin Parnall, sailmaker, and so forth

S. Wright, boot maker

Samuel Kendrick, fancy goods wholesale

J . Collins & Sons, tobacconists

Esau Callow, baker

William Edward Vaughan, dyer & scourer

Smith & Son, cabinet makers

J . Way, tobacconist

Frederick Snary, photographer

Henry Higgs, hatter

Alice Tilley, porter stores

Thomas H. Pengelly, printer

Isaacs Bros., Birmingham warehouse

William White, provision curer

William Ring & Co., grocers

A. Nicholls, Birmingham warehouse

John Saunders, clothier & outfitter

Albert H. Sage, hatter

John Howe, boot maker

A. Webb, hat manufacturer

Charles Clarke, confectioner

Mrs F. Maggs, milliner

John Wrentmore, bedding makers

T. B. Reeves, beer retailer

Warren and Carle, file companies

William Burton, baker

Henry Perry, pie house

Susan Davie, dairy .

Thomas H. W. Hall, confectioner

Thring & Co., grocers

Robert Salter, baker

Frederick Rees, vict, George and Dragon (pub)

George & Dragon Castle Street, corner of Queen Street

1753 John Woolfe / 1792 – 1800 Richard Cox / 1826 – 31 John Gifford / 1834. J. S. Rowe / 1837 M. Hazeldine / 1839 – 48 John Shave 1849 John Downing / 1851 Caroline Neale / 1853 – 55 William Kirk / 1856 – 60 William P. Tapp / 1863 Sarah Nichols / 1865 W. Miles 1866 William Griffiths / 1867 – 68 Richard Mallard / 1869 Frederick Clark / 1871 – 76 Frederick Rees / 1877 to 1885 Rueben Stephens 1886 – 1904 Michael Clune / 1906 James Russell / 1909 Charles Godfrey / 1914 Alfred Caines / 1917 Lily May possibly Caines 1921 Thomas Quigley / 1925 – 28 George Tyler.

Fardon & Townshend, drysalters (Drysalters have been dealers in a range of chemical products, such as glue, varnish, dye and colourings)

Harry Lorymore Howell, soap companies

Cowley A. Tyndall, ironmongers

A. Caird, druggist

William Hatch, boot maker

James Bessell & Sons, linen drapers

Lane & Co, wholesale keep makers

Charles Stevens, vict, Old Castle Tavern (pub) bristolslostpubs.eu/page47.html

The Old Castle was destroyed by bombs throughout the world war two, along with the rest of Castle Street and surrounding region. J W Lane, Castle Street were listed in 1870 they were trading as staymakers at the same address as the Old Castle Tavern.

Howes Bros, hat companies

Prince, Son, & Holloway, undertakers

Priscilla Nott, boot maker

Thomas Gale, currrier

George Jones, hat manufacturer

Richard Fox Gee, pawnbroker

William Pingstone, basket maker

Alfred Brooks, dyer, cleaner, and furrier

John M. S. Tozer & Co. grocers

John Wilmot, carpenter

Samuel Stanmore, vict, Three Cups & Salmon (pub)

Three Cups & Salmon, Castle Street

1851 – 67 James Fisher / 1868 to 1883 Samuel Stanmore / 1885 – 89 John Clark / 1891 – 96 Arthur Chapman / 1897 Albert Sampson 1899 James Thomas / 1901 Jesse Thomas / 1904 James Attwood / 1906 William Rogers / 1909 Jessie Maxwell Taylor 1914 – 25 William Peters / 1928 – 35 Samuel Warren / 1937 – 38 Annie Warren.

James W. Pascoe, japanner, & metalworking

Thomas Lansdown Day, china dealer

Joseph Michael, pawnbroker

William Henry Cowlin, boot maker

Collins and Champion, cork cutters

Charles Jackson, boot maker

Schweppe & Co., soda water companies

Keeping & Co. tobacconists

Thomas Stroud, plumber

William Hall, grocer

George William Skinner, cap manufacturers

George D. Whereat, ironmonger

Thomas Tanner, ale shops

George Edward Fear, furrier

Stopford & Co. hat manufacturers, Castle house

J . Skeates, saddler

William Skeates, jeweller

Charles Irvine, boot warehouse

Gordon & Co. clothiers & outfitters

Printers Library

Specific Baptist Meeting Property

Naish & Co., mfrs. patent cotton

Lugg & Co. wholesale boot companies

Webb, Fardon & Co, druggists

Charles Thomas Ovens, haberdasher

John Cory Withers, hatter

Coalbrookdale Co, iron casting warehouse

T. Harris, gasfitter

Price & Eastman, wire blind maker

H. Goldsborough, embroidery maker

William Edward Goldsbrough, tobacconist

G. Garlick, hatter

W. Jennings, draper

Castle Street (Lower), bottom of Castle Street to Broad Weir

1859 Henry Blackburn, four Reduce Castle Street, Bristol

www.flickr.com/pictures/brizzlebornandbred/8394767196/

Cate’s Cottages, Black Horse Lane, Clifton

Cathay, Colston Parade, Redcliff Hill to Langton Street

Being close to the river this street was possibley named in connection with trading routes to China. The once lawless and notorious district of Cathay where the Pirate Blackbeard was born and bred.

Samuel Webber, grocer

Thomas Osmond Mills, baker

William Kenvin, tailor and draper

Sarah Eve, goldsmith and jeweller

Mrs Rachel Morgan

William Coumbe

Robert Gast

Edward and James Charles, tailors, and so forth.

Charles Thomas

William Winter, lodging house

Henry Carey, relieving officer, registrar of births and deaths

Henry Hunt, vict, Rising Sun (pub)

Rising Sun, Cathay, Redcliff

1837 – 39. Benjamin Williams / 1840 to 1848. Sarah Williams / 1849 to 1854. George Roe / 1855. George Woolcott 1858. William Britton / 1860 – 69. Charlotte Warburton / 1871 – 77. Henry Hunt / 1878 to 1891. Joseph Hawkins 1892 – 99. Alfred Hussey / 1901. Rose Hussey / 1904 to 1922. William Spratt / 1923 to 1935. Mary Spratt 1935 to 1937. Catherine Spratt / 1938 to late 40’s. Ada Drake / 1950 – 53. Thomas Sayers portion of an e mail sent in by Mike Meechem: Catherine Spratt followed Mary Spratt in 1935 until 1937 when my grandfather sold the pub to the Drake Family members. Mrs Ada Drake was the publican until the late 1940’s. It suffered bomb harm throughout the war and a fire in the roof. Owing to a lack of water at the time attempts have been made to manage the fire with beer!!!

Charles Very good, commission agent

James Jeffery

William L. Harris, marble and stone sculptor

William Banner, builder & undertaker

William W. Smith, accountant

Thomas Spurl, ship rigger

Elizabeth J . Tucker, school

Daniel Richards

William Edward Coombs, carpenter

Charles Grimsbey

Benjamin Harding, grocer, and so on.

William Dyment, boot maker

John Lewis

Elizabeth Jenkins, vict, Kings Head (pub) bristolslostpubs.eu/page163.html On the corner with Somerset Spot the King’s Head was demolished in 1959 when the area was redeveloped.

(Somerset Spot)

Walter Sellick

John Holder, railway guard

Thomas Coates, bookbinder

Samuel Farley, pork butcher

Henry Web page, greengrocer

Mary Hardwidge, shopkeeper

William Kinnersly, tea dealer & grocer

Martha Edwards, news-agent

James Low, baker

William Tuck, butcher

Richard Lewis, Cathay brewery

Henry Brice, butcher

Edward Robertson, carpenter & grocer

William Wreford Palmer

Charles Usher, shopkeeper

Joseph Thatcher

Benjamin Smith, vict, Ship (pub)

Ship Inn, Cathay

1775. William Wyatt / 1792. William Hughes / 1794. Edward Carter / 1800 – 06. Thomas Smith / 1816 – 23. John Harford 1826 – 34. William Gammon / 1837 – 40. John Hathaway / 1841 – 42. William Brown / 1844 – 53. George Godfrey 1854 to 1891. Benjamin Smith / 1892 – 99. Thomas Hookway Gange / 1901. Henry Hulbert / 1904 – 09. Walter Pomphrey 1914. Henry Walters / 1917 – 21. Thomas Thomas / 1925. Alfred Tapper / 1928. Joseph Glennell / 1931. Edward Sanders 1935 – 44. George Sixsmith / 1950 – 53. Lilian Sixsmith / 1960 – 62.

Dennis Roberts.

Cathay Parade, Cathay, Redcliff

Robert Atkins, accountant

Catherine Mead Row, Catherine Mead Street to Dean Lane

The following extracts from the ‘Homes of the Bristol Poor’ – published by the Bristol Mercury in 1884 – are initial hand accounts of circumstances prevailing in the imply streets of the time.

The great army of the poor in Catherine Mead Street, has elevated, and none but those who are continually in their properties can have any conception of the hopeless lot of several with empty rooms, blank firesides, bare cupboards and hungry youngsters, whose bodies are scarcely covered by the few rags drawn over them.

There is a wholesome horror of the workhouse.

Catherine Place, Cheltenham Road, Stokes Croft

Catherine Street, Richmond Road to Church St, St Philip’s

H. Wright. beer retailer

Hannah Luff, beer retailer

Ellen Bryant, rope and twine maker

A. Lombardini, beer retailer

George Davis, grocer

Catherine Mead St. East St. to Dean Lane, Bedminster

Chas. Selway, baker

William Sandy, tobacconist

William Giles, grocer

Harry Gunning, tailor and draper

Rebecca Rice, vict, Catherine Home (pub)

Cattle Market Road

The cattle marketplace was established right here in 1830. In 1874 the Fantastic Western and Midland Railways boards reconstructed it.

Cave Street, Portland Square to Wilder Street

Stephen Cave, resided in Brunswick Square.

John Cave & Co. colour companies have been listed in 1793.

Samuel Platnaner

Thomas Jewell

Thomas Gibbs

S. Hodges

Edwin P. Green

Mrs Hawkins

Alfred Munro

Portland Coaching Academy, Thomas Bibbing

Alfred Sharland

Mrs Evans

John Vaughan

Benjamin T. Gough

Hemy Merry

William B. Lanham

Mary Wensley

John Thomas Chase

John P. Donovan