A few nice china auto molds manufacturers images I found:

China

Nice China Interior Auto Parts Mold photos

A few nice china interior auto parts mold images I found:

Nice China Plastic Parts For Car Manufacturer photos

Some cool china plastic parts for car manufacturer images:

Nice China Wheel Cover Mould photos

Some cool china wheel cover mould images:

Steven F. Udvar-Hazy Center: Northrop P-61C Black Widow

Image by Chris Devers

Compare & contrast:

Northrop P-61C Black widow:

* Front view

* Above view

Star Wars ARC-170 Fighter:

* Official page

* Wikia

* Wikipedia

* Toy review

I put it to you that they’re the SAME THING.

* twin engines

* double-cockpit in front

* gunner’s cockpit in back

* broad wing coming out from the middle

• • • • •

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum: Steven F. Udvar-Hazy | Northrop P-61C Black Widow:

The P-61 Black Widow was the first U.S. aircraft designed to locate and destroy enemy aircraft at night and in bad weather, a feat made possible by the use of on-board radar. The prototype first flew in 1942. P-61 combat operations began just after D-Day, June 6, 1944, when Black Widows flew deep into German airspace, bombing and strafing trains and road traffic. Operations in the Pacific began at about the same time. By the end of World War II, Black Widows had seen combat in every theater and had destroyed 127 enemy aircraft and 18 German V-1 buzz bombs.

The Museum’s Black Widow, a P-61C-1-NO, was delivered to the Army Air Forces in July 1945. It participated in cold-weather tests, high-altitude drop tests, and in the National Thunderstorm Project, for which the top turret was removed to make room for thunderstorm monitoring equipment.

Transferred from the United States Air Force.

Manufacturer:

Northrop Aircraft Inc.

Date:

1943

Country of Origin:

United States of America

Dimensions:

Overall: 450 x 1500cm, 10637kg, 2000cm (14ft 9 3/16in. x 49ft 2 9/16in., 23450.3lb., 65ft 7 3/8in.)

Long Description:

The P-61 Black Widow was the first United States aircraft designed from the start to find and destroy other aircraft at night and in bad weather. It served in combat for only the final year of World War II but flew in the European, Mediterranean, Pacific, and China-Burma-India theaters. Black Widow crews destroyed 127 enemy aircraft and 18 robot V-1 buzz bombs.

Jack Northrop’s big fighter was born during the dark days of the Battle of Britain and the London Blitz in 1940. British successes against German daylight bombers forced the Luftwaffe (German Air Force) to shift to night bombing. By the time Royal Air Force (RAF) Spitfires could launch, climb out, and then try to intercept these raids, the bombers crews had usually dropped their loads and turned for home. An aircraft was needed to patrol the skies over England for up to seven hours during the night, and then follow radar vectors to attack German aircraft before they reached their target. U.S. Army Air Corps officers noted this requirement and decided that America must have a night fighter if and when it entered the war.

The Army awarded a contract to Northrop on January 30, 1941. The resulting design featured twin tail booms and rudders for stability when the aircraft closed in behind an intruder. It was a large aircraft with a big fuel load and two powerful engines. Armament evolved into four 20 mm cannons mounted in the belly firing forward and a powered, remote-controlled turret on top of the center fuselage equipped with four .50 cal. machine guns. The three-man crew consisted of the pilot, a gunner seated behind him, and a radar observer/gunner at the rear behind the gun turret. Only the pilot could fire the cannons but any of the three could operate the machine guns.

Simultaneously, work was proceeding, at a laboratory run by the Massachusetts Institute of Technology, to develop the airborne radar set. The Army tested an early design in a Douglas B-18 in 1941. The much-improved SCR-520 set was ready by early 1942. Meanwhile, Army enthusiasm for the XP-61 produced another contract on March 10, 1941, for 13 service-test YP-61s. Even before these airplanes flew, Northrop received orders for 410 production machines! Northrop test pilot Vance Breeze flew the aircraft on May 26, 1942. Although the Black Widow was nearly as large as a medium bomber, it was a true fighter. The only prohibited flight maneuvers were outside loops, sustained inverted flight, and deliberate spins.

As Northrop advanced the design toward production, supply problems arose and modifications became necessary. The 4-gun top turret was the same type fitted to the top forward position on the Boeing B-29 Superfortress (see NASM collection) and that bomber had production priority over the P-61. As a result, several hundred P-61s did not have this turret. Those that did experienced buffeting when the turret was traversed from side to side and a fix took time. By October 1943, the first P-61s were coming off the line. Training started immediately, and the first night fighters arrived in the European Theater by March 1944. Combat operations began just after D-Day (June 6) and the Black Widows quickly departed from their original role as defensive interceptors and became aggressors. They flew deep into German airspace, bombing and strafing trains and road traffic and making travel difficult for the enemy by day and at night.

P-61s arrived in the Pacific Theater at about the same time as the European Black Widows. For years, the Japanese had operated lone bombers over Allied targets at night and now U. S. fighters could locate and attack them. However, on June 30, 1944, a Mitsubishi BETTY (see NASM collection) became the first P-61 kill in the Pacific. Soon, Black Widows controlled the night skies. On the night of August 14-15, a P-61 named "Lady in the Dark" by her crew encountered an intruding Nakajima Ki-43 Hayabusa (Peregrine Falcon) OSCAR (see NASM collection) and eventually forced it into the sea without firing a shot. Although the war was officially over, no one was sure that all of the Japanese had heard the message and stopped fighting. The American night fighters flew again the next night and "Lady in the Dark" again found a target. It was a Nakajima Ki-44 Shoki (Demon) TOJO and the fighters maneuvered wildly as they attempted to gain an advantage. The P-61 crew lost and reacquired the Ki-44 several times then finally lost it for good and returned to base. The next day ground troops found the wrecked TOJO. In the darkness, Lady in the Dark’s crew had forced the Japanese pilot to fly into the ground, again without firing a shot.

With the war over, the Army cancelled further production. Northrop had built 706 aircraft including 36 with a highly modified center fuselage. These F-15As (later redesignated RF-61C) mounted a number of cameras in the nose and proved able reconnaissance platforms. Many of these airplanes participated in the first good aerial photographic survey of the Pacific islands. A few, plus some special purpose P-61s, stayed in active service until 1950.

NASM’s Black Widow is a P-61C-1-NO, U.S. Army Air Forces serial number 43-8330. Northrop delivered it to the Army on July 28, 1945. By October 18, this P-61 was flying at Ladd Field, Alaska, in cold weather tests and it remained there until March 30, 1946. This airplane later moved to Pinecastle Air Force Base, Florida, for participation in the National Thunderstorm Project. The project’s goal was to learn more about thunderstorms and to use this knowledge to better protect civil and military airplanes that operated near them. The U. S. Weather Bureau and the National Advisory Committee for Aeronautics (NACA) undertook the study with cooperation from the Army Air Forces and Navy. With its radar and particular flight characteristics, the P-61 was capable of finding the most turbulent regions of a storm, penetrating them, and returning crew and instruments intact for detailed study.

Pinecastle personnel removed the guns and turret from 43-8330 in July 1946 to make room for new equipment. In September, the aircraft moved to Clinton County Army Air Base, Ohio, where it remained until January 1948. The Air Force then assigned the aircraft to the Flight Test Division at Wright-Patterson Air Force Base, Ohio. After declaring the airplane surplus in 1950, the Air Force stored it at Park Ridge, Illinois, on October 3 along with important aircraft destined for the National Air Museum.

But 43-8830 was not done flying. NACA asked the Smithsonian to lend them the aircraft for use in another special program. The committee wanted to investigate how aerodynamic shapes behaved when dropped from high altitude. The Black Widow arrived at the Ames Aeronautical Laboratory, Naval Air Station Moffett Field, California, on February 14, 1951. NACA returned the aircraft and delivered it to the Smithsonian at Andrews Air Force Base, Maryland, on August 10, 1954. When the engines shut down for the last time, this P-61 had accumulated only 530 total flight hours. Smithsonian personnel trucked it to the Paul Garber Facility in Suitland, Maryland. In 2006, the aircraft was preserved and assembled at the Udvar-Hazy Center. The three different paint schemes from its past service life have been revealed by carefully removing individual layers of paint.

Cool China Plastic Parts For Car Manufacturer images

Some cool china plastic parts for car manufacturer images:

92041 china clay tankers Wembley to Dollands Moor 6B37

Image by train_photos

DB Schenker class 92 number 92041 named "Vaughan Williams" painted in EWS two tone railfreight grey livery and a three ‘O’ shaped channel tunnel roundel logo working 6B37 hauling empty NACCO (North American Car Corporation) tankers from Wembley European Freight Operating Centre to Dollands Moor Sidings as part of their return journey to Antwerpen (Antwerp) Docks, Belgium from Irvine Scotland on 28 February 2014. For the route taken see (www.flickr.com/photos/99279135@N05/14289727859/). 92041 traveled down to Wembley earlier in the day as 6M76 photographed at Northampton by Nigel Gould (www.flickr.com/photos/60599026@N05/12831694204/in/photoli…). Prior to this Brian Denton photogrphed these tankers filled with china clay slurry heading northwards towards Scotland on 26 February 2014 (www.flickr.com/photos/brian_dentons_linesidephotos-europe…). Once the tankers arrive back at Antwerpen Docks they are reloaded with china clay slurry (kaolin) made from rocks rich in kaolinite, Al2Si2O5(OH)4, imported from Brazil. This slurry is transported to Irvine, Scotland by 6S94 where it is used by the Finnish company, UPM-Kymmene (United Paper Mills Ltd) Corporation’s at their Caledonian Paper Mill to produce lightweight coated paper for printing magazines, catalogues and brochures.

92041 was assembled by the BRUSH Traction Company Loughborough in 1996, from sub-contracted components e.g. Procor UK bodyshell, Asea Brown Boveri (ABB Rail) traction converters and GTO (Gate Turn-Off thyristor) controlled via the MICAS-S2 electronics system, retractable third rail collector shoes and pantographs made by Brecknell Willis, the engraved aluminium BRUSH traction works plates made by J M Ranger Limited of Leicester and cast aluminium based alloy Crew Depot plaque produced by David Newton of Nottingham. For track to train communications class 92s were fitted with the Siemens International Train Radio (ITR) "chameleon" system which could automatically change over to match local ground systems e.g. at international boarders and allowed the driver to select from a range of language settings. STS Signals Ltd supplied electronic Train Protection and Warning System (TPWS) control units for class 92s as an add on to the Automatic Warning System (AWS) equipment. STS Signals Ltd also developed a twin-lightweight AWS receiver for use on class 92s so that only one receiver was needed to detect both standard strength magnets on lines powered by AC overhead wires (Rx1) as well as the extra strength magnets used on DC third rail lines (Rx2). All non-metallic components of the class 92 were either certified for Eurotunnels fire regulations by the manufacturers or where suppliers could not provide this information products such as the divers seat (made by Chapman Seating Limited) and plastic push buttons were fire tested by BRUSH.

Nice China Car Door Moulding photos

A few nice china car door moulding images I found:

Nice Auto Moulds Manufacturers China photos

Some cool auto moulds manufacturers china images:

Nice China Auto Moulds Manufacturers photos

Check out these china auto moulds manufacturers images:

Nice China Mould Make Maker photos

A few nice china mould make maker images I found:

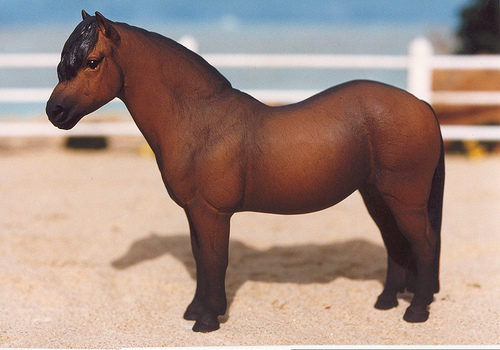

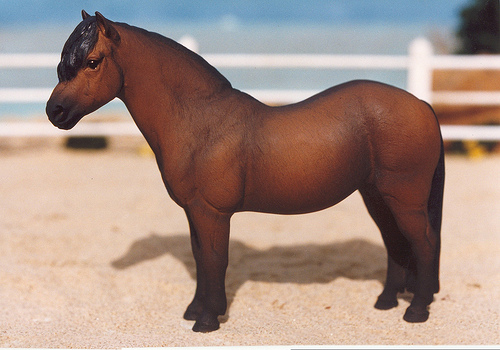

FOR SALE: Original North Light “Kitley Ladybird” – Dartmoor Pony mare

Image by appaIoosa

Model # P1133 – bay

Size: 5-3/4"H x 6-1/2"L

Original mold, produced by North Light.

Identifying marks & logos:

On belly: "KITLEY LADYBIRD "

On right buttock cheek: " © North Light 1986 "

Inside right hind leg: " Godfrey "

Inside left hind leg: " MADE IN UK

This is a model of the classic British breed, the Dartmoor. These ponies are hardy and well balanced, originating in Devon, England. This breed is closely related to the Exmoor Pony and probably descended from the same stock. These ponies roamed wild over the rugged moorlands of southwestern Devon for many centuries. Toward the end of the 19th century, the breed’s traits were stabilized by the creation of the Dartmoor Pony Breed Society, with standard requirements. The maximum height for this pony is 12.2 hands high at the withers. She is a well-balanced pony with small head, ears and eyes. The mane and tail are thick and full. The neck is wide, the chest deep and muscular and the shoulders are strong and sloping.

This North Light model is a lovely representative of a Dartmoor Pony from the North Light Native Pony Series.

|||****************************|||

North Light model horse figurines are made of a porcelain and resin composition, which allow for the extensive mold detailing (some with individual hair detailing, braided manes & tails, etc) that is very evident in the finish. The figurines are finished in a studio where they are airbrushed with the body color and shading required for the particular breed piece. Next comes the hand detailing , which can be extensive, depending on the horses’ color pattern. Pinto and appaloosa patterns require extensive hand work, and vary greatly from horse to horse. Facial features also receive hand detailing, with expressive, lifelike eyes which have a final gloss application to make them look moist and realistic. Touches of pink are added to muzzles. Nostrils are darkened inside to add depth.

With this degree of hand detailing, each model horse will vary slightly.

North Light is a company located in Stoke-On-Trent, Staffordshire, England. The area is famous for its potteries and figurines, including the well known Wedgwood, Beswick and Royal Doulton brands. In 2005, the North Light factory was sold – including all existing North Light molds – to the company: WADE CERAMICS LTD (yes, the same company that made those little whimsy figurines found in red rose tea boxes years ago). Wade repackaged the existing North Light horses under their new trademark and resold them within the Wade division as "North Light @ Wade" horses.

Directly from Wade Co. website, verbatim:

———————————–

Contributed by Carol Atrak

Monday, 18 July 2005

We have pleasure in announcing that Wade has purchased certain assets from Dennis Doyle of the North Light resin figurine range. North Light, which will trade as a division within Wade as "North Light @ Wade", is famous for its range of dogs, farm animals, horses and wildlife figurines. They are manufactured in resin and hand painted. The "Classic Dog and Horse Ranges" are finished in marble, china blue, bronze, Monet and other effects to grace the sideboards and coffee tables of the World’s finest homes.

Managing Director, Paul Farmer said, "North Light @ Wade" will bring a new dimension to Wade’s figurine capability and Wade’s mechanisms for online purchases of its ceramic products will be adapted to cater for North Light products too. We are also looking forward to improving our ceramic hand painting techniques which come with the North Light asset purchase."

Artists, Guy Pocock and Anne Godfrey, have been retained to continue modelling new lines and Clare Beswick, from that famous family of figurine makers which bears her name, has been appointed Sales and Product Manager for North Light @ Wade.

The manufacture has been moved from Biddulph to a separate resin area within Wade’s Royal Victoria Pottery in Burslem.

In 2008, Wade announced they would no longer produce the North Light @Wade horses (and dogs) at the factory (in the UK). Instead they decided to release a new line: "North Light @ Wade Premier Collection" (consisting of 17 horses and 22 dogs) – to be produced in China. Many of the existing NL horses you see being sold on eBay (and elsewhere) today, bear the "made in China" sticker, along with the NL backstamp.

In 2009, Wade ceased production altogether on all existing North Light models . Today, North Light horses are no longer being produced, sold or marketed by Wade Ceramics, making these horses highly sought after, valuable and rare.

I have no idea what the Wade Co. decided to do with all the existing North Light horses. Some say they sold the existing molds to a company in China.

If your North Light horse has the "©North Light Made in the UK" backstamp, you have a very rare & valuable collectible indeed!

Nice Auto Moulds Factory China photos

Check out these auto moulds factory china images:

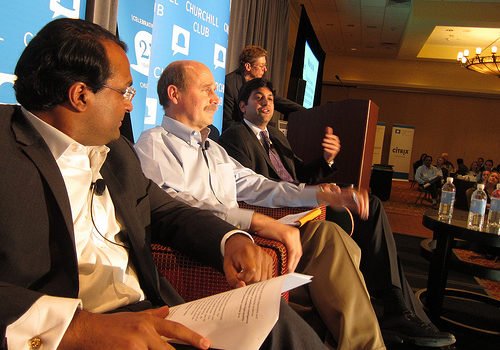

Churchill Club Top 10 Tech Trends Debate

Image by jurvetson

I just got back from the Churchill Club’s 13th Annual Top 10 Tech Trends Debate (site).

Curt Carlson, CEO of SRI, presented their trends from the podium, which are meant to be “provocative, plausible, debatable, and that it will be clear within the next 1-3 years whether or not they will actually become trends.”

Then the panelists debated them. Speaking is Aneesh Chopra, CTO of the U.S., and smirking to his left is Paul Saffo, and then Ajay Senkut from Clarium, then me.

Here are SRI’s 2011 Top 10 Tech Trends [and my votes]:

Trend 1. Age Before Beauty. Technology is designed for—and disproportionately used by—the young. But the young are getting fewer. The big market will be older people. The aging generation has grown up with, and is comfortable with, most technology—but not with today’s latest technology products. Technology product designers will discover the Baby Boomer’s technology comfort zone and will leverage it in the design of new devices. One example today is the Jitterbug cell phone with a large keypad for easy dialing and powerful speakers for clear sound. The trend is for Baby Boomers to dictate the technology products of the future.

[I voted YES, it’s an important and underserved market, but for tech products, they are not the early adopters. The key issue is age-inspired entrepreneurship. How can we get the entrepreneurial mind focused on this important market?]

Trend 2. The Doctor Is In. Some of our political leaders say that we have "the best medical care system in the world". Think what it must be like in the rest of the world! There are many problems, but one is the high cost of delivering expert advice. With the development of practical virtual personal assistants, powered by artificial intelligence and pervasive low-cost sensors, “the doctor will be in”—online—for people around the world. Instead of the current Web paradigm: “fill out this form, and we’ll show you information about what might be ailing you”, this will be true diagnosis—supporting, and in some cases replacing—human medical practitioners. We were sending X-rays to India to be read; now India is connecting to doctors here for diagnosis in India. We see the idea in websites that now offer online videoconference interaction with a doctor. The next step is automation. The trend is toward complete automation: a combination of artificial intelligence, the Internet, and very low-cost medical instrumentation to provide high-quality diagnostics and advice—including answering patient questions—online to a worldwide audience.

[NO. Most doctor check-ups and diagnoses will still need to be conducted in-person (blood tests, physical exams, etc). Sensor technology can’t completely replace human medical practitioners in the near future. Once we have the physical interface (people for now), then the networking and AI capabilities can engage, bringing specialist reactions to locally collected data. The real near-term trend in point-of-care is the adoption of iPads/phones connected to cloud services like ePocrates and Athenahealth and soon EMRs.]

Trend 3. Made for Me. Manufacturing is undergoing a revolution. It is becoming technically and economically possible to create products that are unique to the specific needs of individuals. For example, a cell phone that has only the hardware you need to support the features you want—making it lighter, thinner, more efficient, much cheaper, and easier to use. This level of customization is being made possible by converging technical advances: new 3D printing technology is well documented, and networked micro-robotics is following. 3D printing now includes applications in jewelry, industrial design, and dentistry. While all of us may not be good product designers, we have different needs, and we know what we want. The trend is toward practical, one-off production of physical goods in widely distributed micro-factories: the ultimate customization of products. The trend is toward practical, one-off production of physical goods in widely distributed micro-factories: the ultimate customization of products.

[NO. Personalization is happening just fine at the software level. The UI skins and app code is changeable at zero incremental cost. Code permeates outward into the various vessels we build for it. The iPhone. Soon, the car (e.g. Tesla Sedan). Even the electrical circuits (when using an FPGA). This will extend naturally to biological code, with DNA synthesis costs plummeting (but that will likely stay centralized in BioFabs for the next 3 years. When it comes to building custom physical things, the cost and design challenges relegate it to prototyping, tinkering and hacks. Too many people have a difficult time in 3D content creation. The problem is the 2D interfaces of mouse and screen. Perhaps a multitouch interface to digital clay could help, where the polygons snap to fit after the form is molded by hand.]

Trend 4. Pay Me Now. Information about our personal behavior and characteristics is exploited regularly for commercial purposes, often returning little or no value to us, and sometimes without our knowledge. This knowledge is becoming a key asset and a major competitive advantage for the companies that gather it. Think of your supermarket club card. These knowledge-gatherers will need to get smarter and more aggressive in convincing us to share our information with them and not with their competitors. If TV advertisers could know who the viewers are, the value of the commercials would go up enormously. The trend is technology and business models based on attracting consumers to share large amounts of information exclusively with service providers.

[YES, but it’s nothing new. Amazon makes more on merchandising than product sales margin. And, certain companies are getting better and better at acquiring customer information and personalizing offerings specifically to these customers. RichRelevance provides this for ecommerce (driving 25% of all e-commerce on Black Friday). Across all those vendors, the average lift from personalizing the shopping experience: 15% increase in overall sales and 8% increase in long-term profitability. But, simply being explicit and transparent to the consumer about the source of the data can increase the effectiveness of targeted programs by up to 100% (e.g., saying “Because you bought this product and other consumers who bought it also bought this other product" yielded a 100% increase in product recommendation effectiveness in numerous A/B tests). Social graph is incredibly valuable as a marketing tool.]

Trend 5. Rosie, At Last. We’ve been waiting a long time for robots to live in and run our homes, like Rosie in the Jetsons’ household. It’s happening a little now: robots are finally starting to leave the manufacturing floor and enter people’s homes, offices, and highways. Robots can climb walls, fly, and run. We all know the Roomba for cleaning floors—and now there’s the Verro for your pool. Real-time vision and other sensors, and affordable precise manipulation, are enabling robots to assist in our care, drive our cars, and protect our homes and property. We need to broaden our view of robots and the forms they will take—think of a self-loading robot-compliant dishwasher or a self-protecting house. The trend is robots becoming embedded in our environments, and taking advantage of the cloud, to understand and fulfill our needs.

[NO. Not in 3 years. Wanting it badly does not make it so. But I just love that Google RoboCar. Robots are not leaving the factory floor – that’s where the opportunity for newer robots and even humanoid robots will begin. There is plenty of factory work still to be automated. Rodney Brooks of MIT thinks they can be cheaper than the cheapest outsourced labor. So the robots are coming, to the factory and the roads to start, and then the home.]

Trend 6. Social, Really. The rise of social networks is well documented, but they’re not really social networks. They’re a mix of friends, strangers, organizations, hucksters—it’s more like walking through a rowdy crowd in Times Square at night with a group of friends. There is a growing need for social networks that reflect the fundamental nature of human relationships: known identities, mutual trust, controlled levels of intimacy, and boundaries of shared information. The trend is the rise of true social networks, designed to maintain real, respectful relationships online.

[YES. The ambient intimacy of Facebook is leading to some startling statistics on fB evidence reuse by divorce lawyers (80%) and employment rejections (70%). There are differing approaches to solve this problem: Altly’s alternative networks with partioning and control, Jildy’s better filtering and auto-segmentation, and Path’s 50 friend limit.]

Trend 7. In-Your-Face Augmented Reality. With ever-cheaper computation and advances in computer vision technology, augmented reality is becoming practical, even in mobile devices. We will move beyond expensive telepresence environments and virtual reality games to fully immersive environments—in the office, on the factory floor, in medical care facilities, and in new entertainment venues. I once did an experiment where a person came into a room and sat down at a desk against a large, 3D, high-definition TV display. The projected image showed a room with a similar desk up against the screen. The person would put on 3D glasses, and then a projected person would enter and sit down at the other table. After talking for 5 to 10 minutes, the projected person would stand up and put their hand out. Most of the time, the first person would also stand up and put their hand into the screen—they had quickly adapted and forgotten that the other person was not in the room. Augmented reality will become indistinguishable from reality. The trend is an enchanted world— The trend is hyper-resolution augmented reality and hyper-accurate artificial people and objects that fundamentally enhance people’s experience of the world.

[NO, lenticular screens are too expensive and 3D glasses are a pain in the cortex. Augmented reality with iPhones is great, and pragmatic, but not a top 10 trend IMHO]

Trend 8. Engineering by Biologists.

Biologists and engineers are different kinds of people—unless they are working on synthetic biology. We know about genetically engineered foods and creatures, such as gold fish in multiple other colors. Next we’ll have biologically engineered circuits and devices. Evolution has created adaptive processing and system resiliency that is much more advanced than anything we’ve been able to design. We are learning how to tap into that natural expertise, designing devices using the mechanisms of biology. We have already seen simple biological circuits in the laboratory. The trend is practical, engineered artifacts, devices, and computers based on biology rather than just on silicon.

[YES, and NO because it was so badly mangled as a trend. For the next few years, these approaches will be used for fuels and chemicals and materials processing because they lend themselves to a 3D fluid medium. Then 2D self-assembling monolayers. And eventually chips , starting with memory and sensor arrays long before heterogeneous logic. And processes of biology will be an inspiration throughout (evolution, self-assembly, etc.). Having made predictions along these themes for about a decade now, the wording of this one frustrated me]

Trend 9. ‘Tis a Gift to be Simple. Cyber attacks are ever more frequent and effective. Most attacks exploit holes that are inevitable given the complexity of the software products we use every day. Cyber researchers really understand this. To avoid these vulnerabilities, some cyber researchers are beginning to use only simple infrastructure and applications that are throwbacks to the computing world of two decades ago. As simplicity is shown to be an effective approach for avoiding attack, it will become the guiding principle of software design. The trend is cyber defense through widespread adoption of simple, low-feature software for consumers and businesses.

[No. I understand the advantages of being open, and of heterogencity of code (to avoid monoculture collapse), but we have long ago left the domain of simple. Yes, Internet transport protocols won via simplicity. The presentation layer, not so much. If you want dumb pipes, you need smart edges, and smart edges can be hacked. Graham Spencer gave a great talk at SFI: the trend towards transport simplicity (e.g. dumb pipes) and "intelligence in the edges" led to mixing code and data, which in turn led to all kinds of XSS-like attacks. Drive-by downloading (enabled by XSS) is the most popular vehicle for delivering malware these days.]

Trend 10. Reverse Innovation. Mobile communication is proliferating at an astonishing rate in developing countries as price-points drop and wireless infrastructure improves. As developing countries leapfrog the need for physical infrastructure and brokers, using mobile apps to conduct micro-scale business and to improve quality of life, they are innovating new applications. The developing world is quickly becoming the largest market we’ve ever seen—for mobile computing and much more. The trend is for developing countries to turn around the flow of innovation: Silicon Valley will begin to learn more from them about innovative applications than they need to learn from us about the underlying technology.

[YES, globalization is a megatrend still in the making. The mobile markets are clearly China, India and Korea, with app layer innovation increasingly originating there. Not completely of course, but we have a lot to learn from the early-adopter economies.]