For injection moulder services, form originators ought to consider the utilization of cold runner shut-offs to furnish disintegrates with assembling flexibility. A portion of the regular employments of runner shut-offs include:

to incidentally close off the stream to harmed holes until form fix can be performed, to choose distinctive com binations of shape cavities to run in a family shape compliant with creation prerequisites, and to modify the gating and stream in a multigated part.

In that capacity, runner shut-offs can be utilized in precision plastic injection mold factory by the disintegrate to abstain from embellishment damaged or undesired parts just as improve the nature of multigated parts without retooling. The utilization of runner shut offs to incidentally seal harmed cavities is fairly questionable since it 1) expects changes to the embellishment machine measure conditions (particularly shot size and infusion speed), and 2) can unbalance or in any case adjust the stream and warmth move between pits. Except if the disintegrate re-qualifies the trim cycle for the new depression design, hole shut-offs ought not be utilized in business creation for high accuracy forming applications.

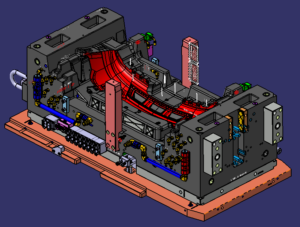

An isometric, detonated get together perspective on a runner shut-off plan is appeared. In this plan of oem/odm industrial mould factory, a pivoting round and hollow supplement, thing 50, is held between an external packaging, 40, and a retainer, 60, that adjoins the back plane of a barrel shaped pocket cut into the form plate. The runner supplement might be promptly turned with the form introduced in the embellishment machine. A spring-stacked ball is utilized to connect with grooves, 54, on the rear of the addition to guarantee that the supplement doesn’t accidentally turn during ensuing embellishment cycles. While the plan gives a runner a”T”branch, the shut-off get together comes incomplete and can be given different runner setups, the most well-known being”T,””L,”and straight. Economically accessible shut-offs are accessible for around $1 50 for use with runner measurements going from 2 mm to 9.5 mm. When planning the feed system for cold runner forms, the shape planner ought to determine runner widths that are machined with promptly accessible cutting apparatuses.

The most usually accessible sizes for tightened, square, and ball end plants are 1/32″,1/16″, 3/32″,1/8″, 3/16″, 1/4″,5/16″, 3/8″, 7/16″,1/2″, 2 mm, 3 mm, 4 mm, 4.5 mm, 5 mm, 6 mm, 8 mm, 10 mm, and 12 mm. To accomplish the most effortlessly delivered cold runner plan, it might be important to adjust the measurements to standard sizes and check the exhibition of the plan with investigation. Nonetheless, if nonstandard runner sizes accommodate less material use and more adjusted dissolve stream, at that point nonstandard runner widths can and ought to be indicated.

Hot runner systems are correspondingly accessible with a scope of standard bore sizes, commonly stepped in 1 or 2 mm increases. The standard distances across and plans will fluctuate by hot runner provider. A few providers may give bore distances across of 5, 7, and 9 mm while different providers may give widths of 4, 6, 8, and 10 mm.

Most serious providers of china high precision mold supplier will perform stream examination of the feed system and give suggestions with respect to the hot runner innovation and measuring. Notwithstanding, the form fashioner ought to confirm the suitability of the proposals. Likewise with the detail of custom widths for a cool runner, numerous hot runner providers will give custom measuring at an additional expense. This article is from http://www.automoldchina.com/.