The embellishment of the cover appeared in detail B of high precision plastic injection mould factory presents a completely independent issue identified with the launch of the shaped undercut from the center supplement. As appeared in this detail, the side mass of the shaped top should twist so the lip of the cover can get away from the undermined on the center addition. In the event that the measure of strain brought about by launch is inside the flexible furthest reaches of the material, at that point such undermines can be dependably formed and catapulted from the shape without unique concerns. Indeed, stripper plates are ideal for such launch since they give uniform discharge powers that are almost in _line with the contact power between the embellishment and the center.

The strain, e, brought about by an undercut during launch can be promptly assessed as the measure of avoidance, δ, that the part is needed to go through isolated by the distance, L, across which the diversion is applied, or: ε=δ/L

Index A gives some material properties to different plastics, including the strain to yield. It is seen that most plastics have a strain to yield above 2%, which is a sensible form plan rule. The exemption is vigorously filled materials, which have a lower flexible cutoff and will in general fall flat in a fragile way.

The launch power for a section that is flexibly distorted during discharge can likewise be assessed. To begin with, the pressure in the distorted segment of the part can be determined as the forced strain duplicated by the modulus of the material, E: σ= Ee

This pressure goes about as a loop pressure around the border of the part, like the past examination. The ordinary power is assessed as: Fnormal=σAcontact This power is more noteworthy than the discharge power needed to launch the cup on the contrary side of the shape. Lopsided launch powers can prompt lopsided wear in the form because of bowing minutes applied across the ejector or potentially stripper plates that cause nonuniform weight on guide pins and bushings.

To limit this wear, the thickness of the stripper plate and the size of the guide bushings can be expanded. Furthermore, the stripper plate should be impelled at two areas that are in-accordance with the hub of the depressions rather than one essential issue as shown in high precision molds china.

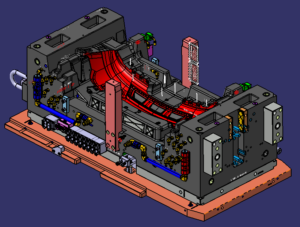

The term”core pull” or”side action”generally alludes to a gadget that withdraws a center toward a path that isn’t resemble to the initial course of the shape. Center pulls permit the embellishment of parts with moderately enormous, complex undermines that may some way or another not be monetarily plausible to deliver.

For instance, the item plan of the bezel may require the trim of sidelong managers and a window as appeared in injection moulder services. To form these highlights, an additional shape embed is needed to give the steel around these highlights. This shape embed should be taken out before the launch of the form and the activation of the discharge framework.

This article is from http://www.automoldchina.com/